Since the founding of Conte Caserta, it has been our aim to make no compromises in the production of our unique Signature Collection when it comes to the quality of materials and workmanship while observing ecological aspects. For this reason, 100% pure, heated tung oil is the only choice for us for the surface treatment of our unique table items made of solid wood.

Why do we recommend surface treatment / wood care?

If left untreated, wood would become brittle over time and lead to cracking. In order to protect wood from signs of wear and embrittlement in the long term – even over generations – and to maintain its beauty, regular care is necessary. Correct surface treatment and care preserves the positive properties of the wood and protects it at the same time.

Which surface treatment is best for solid wood tables?

Pure wood oils and waxes are produced using natural processes. They are environmentally friendly, emphasize the naturalness of the wood and preserve the wood feel. In addition, oiled or waxed wooden surfaces are easy to repair – even partially.

What should you watch out for when using oils or waxes?

Wood oil

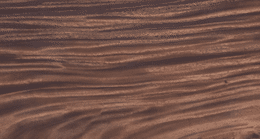

The use of wood oil intensively emphasizes the natural grain of the wood (technically called firing) and brings out the beauty of nature more fascinatingly than any other surface treatment. In the case of oils, a distinction is made between liquid and hardening, as well as between natural, mixed and synthetic oils. All wood oils have a liquid consistency. The main advantage is that wood oil penetrates into the deeper layer of the material, but remains open-pored and breathable. This results in a gentle impregnation, as moisture can only penetrate to a limited extent and is quickly released back into the atmosphere. Wood oils create a semi-gloss finish on the surface. Hardening wood oils harden on contact with oxygen. The hardening process takes a lot of time, which most wood processors are not ready to invest in today’s fast-moving world. By adding chemical additives (siccatives) such as solvents the drying time is significantly accelerated. As a result, wood loses its ecological character, the penetration depth of the oil is reduced and there are harmful vapors. The situation is similar with synthetic wood oils, which are composed purely chemically. With regard to the indoor climate, it should be ensured that no chemical additives have been used.

Liquid, non-hardening oils such as Salad oils, motor oils, etc. tend to go rancid after a while, to stink and to form mold. Liquid oils are not suitable for wood treatment. The only disadvantage of oiled surfaces is that they are subject to wear and tear and require regular post-treatment. Regular, damp wiping and re-oiling of heavily used pieces of furniture such as dining or work tables once or twice a year are sufficient to preserve the furniture for generations.

Wood wax

- The surface protective layer formed by wood wax is neither stable nor permanent

- At slightly higher temperatures, the wax layer becomes soft and sticky areas can form

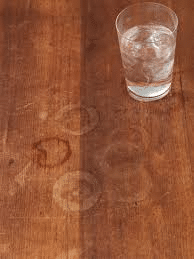

- Although moisture rolls off the waxed surface, any liquids must be removed quickly during everyday use, as the wood remains sensitive due to the purely external protective treatment and water stains can appear, among other things.The wax layer is not completely “tight”, so dirt can penetrate under the layer and into the wood

- Below the wax layer and below the surface, the wood is completely unprotected

- The disadvantages of wood wax make it clear that the use of wood oil is definitely the best way to care for wood, especially for furniture that is subject to heavy use.

Pure tung oil and its benefits

For the reasons mentioned above, wood oil is the classic in the surface treatment of wood, which makes it perfect for the natural surfaces that are so popular today. The most common wood oils are flaxseed oil, walnut oil, poppy seed oil, diestel oil and tung oil.

The specific weight increases while the refractive index is reduced. In contrast to all other natural oils, this makes the tung oil water-repellent and thus prevents the formation of water rings. Tung oil penetrates the wood more deeply than any other wood oil; it penetrates deeply into even the densest wood. In addition, compared to most other oxidative oils, it forms a fine, permanent film that retains its elasticity and moves with the wood. After hardening, the surface is solidified. There is no embrittlement or hairline crack formation on wooden surfaces, as the oil remains elastic even after it has hardened.

The reason why pure tung oil, despite its incomparably good properties, is rarely used by woodworkers, is essentially explained by the following objections:

- Tung oil is comparatively thick and therefore difficult to process. It penetrates the wood only slowly.

- The drying time is very long, which is why chemical thinners are often added.

- High-quality, heated tung oil is comparatively expensive. It costs roughly the same as high-quality French champagne.

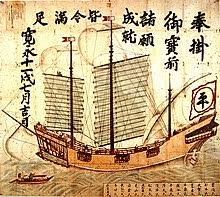

History of Tung Oil

Since Conte Caserta was founded, it has been our aim to make no compromises in the production of our unique Signature Collection in terms of the quality of materials and workmanship, taking into account ecological aspects:

We only use sustainable suar wood for our table tops, as no other type of wood is better suited to be processed in one piece.

All table tops we make are made from just one piece of suar wood. This makes our tables so valuable compared to other tables, the surfaces of which are mostly made of panels glued together.

By using only one piece of Suar wood, the incomparably fascinating grain of the wood is not interrupted. This gives each table its own unique sculptural character.