Briefly:

- Suar wood from Thailand is not sourced from tropical rainforests

- No other type of wood is better suited to be processed in one piece

- Proper drying and sealing protect the wood from cracking

- If treated with propper care furniture made of Suar wood will last for decades and generations

We call it sustainable.

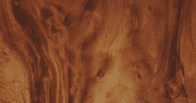

Suar wood has an incomparably fascinating grain and a wide range of colors

The most exciting moment for a Suar wood furniture maker is choosing the wood panels. Each slab differs in its individual color and grain.

The color core of Suar wood clearly sets itself apart from the light-colored sapwood. The sapwood has a whitish to yellowish color, which is distributed over a width of around five to ten centimeters. The color of the heartwood varies depending on the age and location of the tree. It is often characterized by a golden brown, sometimes reddish basic tone. Older trees or trees with little fluid supply can take on all shades of brown up to black brown.

Tabletops made of Suar wood are paintings – painted by nature with a sculptural character. The grain of the trees runs from striped to irregularly veined or it is cloudy. Sometimes “3D grains” develop, which are particularly fascinating.

The results are spectacular color highlights with merging grains in a wide variety of designs without any interruptions. No two slabs are the same, making each one unmistakably unique.

Suar wood is ideal for processing furniture from only one piece of wood

Wood that is processed from only one piece must be stable. Wood from temperate climatic regions is subject to irregular growth, that´s why the well-known annual rings are formed. If moisture is removed from the wood during the drying process, a high level of tension is created in the different wood structures, which leads to cracks when unloading. Tropical wood is also subject to tension in the event of climate fluctuations, but to a much lesser extent, which means that the risk of cracking is lower.

Wood fibers serve the stability of the wood. If the fibers were straight, the long branches of the rain tree would simply break under the high pressure. The fibers of the rain tree are intertwined, like the wires of a cable car, for example. This property gives Suar wood – also compared to other tropical woods – an incomparably high level of stability.

The thinner a wooden slab, the higher the risk of cracking. Therefore, when choosing Suar wooden slabs from one piece, attention should be paid to a panel thickness of 7 to 8.5 cm as thick as possible. With thicker panels, there is a risk that they contain too much residual moisture. Panels with a thickness of less than 7 cm should be stabilized below with embedded steel beams.

Suar wood from Thailand is sustainable

Suar wood originally comes from the South American rainforest. Several hundred years ago Portuguese colonialists brought the seeds of the tree to Southeast Asia, where it was able to spread rapidly thanks to the ideal climatic conditions.

In Thailand, the regulations on logging have tightened drastically since the overexploitation of the Thai primeval forests in the 1980s.

No other country in Southeast Asia has stricter laws on this. Any wood that is intended for export must first be certified by the Thai forest authority. Only wood whose origin has been proven and for which a permit for felling has been granted is certified.